How to Maintain Air Compressor Effectively?

- By: Admin

- 2022-08-09

Appropriate maintenance of an air reciprocating compressor is important to guarantee that it works without a hitch and is safe to utilize. Compressors that are not kept up with appropriately can quit working and can likewise imperil your security while utilizing it. If you have an air compressor, you really want to know how to keep up with the gadget actually. We at G.S Machinery offer the best quality Reciprocating Compressor in Delhi that is simple to maintain. Let’s have a look at some of the useful tips to maintain air compressor.

Safety Valve

The pop off valve or safety valve is a little part on the control unit that consequently sets the air free from the tank on the off chance that the tension in the tank surpasses the preset greatest. This keeps the tank from blasting because of high tension. To guarantee that it's working appropriately, you should check it week by week by pulling the wellbeing valve so it pops back to its unique spot. It should let air out of the tank at some random time and should pop back at around 40-50 PSI. In the event that it doesn't do this, it should be supplanted.

Filter

Generally, every air compressor has an air filter introduced on the admission opening. If yours doesn't then you really want to introduce one. You should check the air channel consistently. You can do this by eliminating the air channel lodging cover. If the filter is filthy, you should have it supplanted to guarantee smooth working of the unit. Stifled air channels will diminish the attractions and effectiveness of the air compressor.

Drain the Tank

Numerous clients neglect to drain the tank in the wake of utilizing the unit. This can prompt rust development inside the tank. You should constantly empty dampness out of the tank by opening the channel valve at the lower part of the tank. Extensive stretches without depleting will decrease the viable air stockpiling limit in the tank and can likewise diminish the life expectancy of the air collector altogether.

Cleaning

You should ensure you keep your air compressor clean consistently. You ought to wipe flotsam and jetsam off from the engine, flywheel, tank, airlines and siphon cooling balances. Most compressors are air cooled and any type of residue or different stores will restrain the successful intensity move from compressor to the encompassing bringing about higher temperature run. This should be finished while the unit is turned off.

Noise

Oftentimes actually take a look at the compressor from surprising commotion. If any shaking sound is heard try to fix every one of the clasp as they will generally relax eventually. If a screeching noise is heard, you should fix plunge belts or supplant drive belts assuming that your compressor is belt driven. Any air releases should be quickly tended to or it will make the compressor run constantly. Air spill from tanks are extremely perilous and compressor should be halted right away.

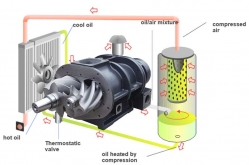

Oil Change

Ensure that the oil level doesn't go underneath the red circle or spot on the oil level sight glass. The oil should be changed consistently or at the 500 hour mark. To replace oil, you should:

- Run the unit for a brief period and permit the oil to heat up

- Turn off the unit

- Hold a compartment under the siphon end

- Eliminate the oil channel plug and permit the oil to gather in the compartment

- Supplant the channel plug

- Fill the crankcase with new oil

Try not to involve engine oil as it could hinder valves and diminish the existence of the unit. Running the compressor without oil or low oil will consequently default guarantee so you should frequently check the oil level.

Pressure Switch

Ensure to check your pressure switch is as yet working in the set reach. Many bad quality tension switches will more often than not lose their exactness in time. Allude the strain dial or check on the tank and note the tension at which the compressor stops, then, at that point, discharge the air from the tank and note the strain when the compressor restarts. Contrast them and the makers setting and contact any compressor administration repairman to recalibrate if needed.

If you are looking for the leading Reciprocating Air Compressors Manufacturers, Exporters India then you can trust on G.S Machinery to buy the the best compressor that suits your requirements and budget.

What Our Client Says

We make sure to provide the unmatched machines to all our clients. With years of expertise, we have established a reputation in the market and always try to attain the trust of our clients.

I have purchased semi automatic pet blowing machine from G.S Machinery. The quality of the machine was very good. Highly recommended machine! I am very satisfied with their product.

-

- Ankit

G.S Machinery is the best compressor manufacturing company. It is the right place to buy reciprocating and screw compressor. Fine quality and prompt delivery.

-

- Rohit

Fully Automatic Pet Blowing Machine Series provided by G.S Machinery offers high productivity. You can trust on G.S Machinery to buy excellent-performing automatic pet blowing machine series at the best price.

-

- Ritesh